W-130-E Seton Furnace - Discontinued*

*PRODUCT DISCONTINUED - This page is for informational purposes only.

Seton claims their boilers will furnish heat faster and hold a fire longer without creating creosote than any stove or wood boiler available.

- Description

- Specifications

- Photos (3)

- Pricing

- Extended Info

- Add Review

*PRODUCT DISCONTINUED - This page is for informational purposes only.

Features:

The Seton Wood Boiler has unique features that make it better than any other wood boiler.

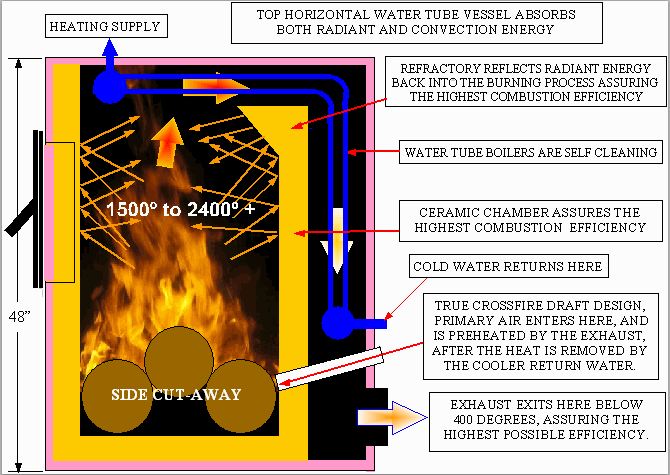

First is the refractory combustion chamber that ensures a very high combustion temperature and a long flame path with enough turbulence to complete the burning of all gases.

Once the wood gases are completely burned the hot gases enter the heat exchange area.

The heat exchanger is a down draft system with the exhaust exiting where the cold water is coming in.

This increases the deferential between the water temperature and the exhaust temperature which lowers the exhaust temperature and increases the thermal transfer efficiency.

The draft air is heated with the exiting exhaust gases after all the available heat is put into the water which increases the combustion temperature without taking heat from the combustion process.

The heat exchanger or boiler, is a water tube design which absorbs more heat per square inch than fire tube boilers, withstands much more pressure and also holds much less water so it responds quicker. Because of the very limited water storage water tube boilers are much safer than fire tube boilers.

Do not confuse downdraft heat exchangers with down draft combustion.

Down draft combustion is where the flames are drawn down into a combustion chamber. Horizontal combustion chambers in downdraft boilers have a problem with the hot gases layering.

For these to burn cleanly they would need to be much longer and have more turbulence or a swirling action.

Although downdraft combustion does burn cleanly when working properly the ashes are drawn down into the combustion chamber and are exited out with the exhaust contributing to particulate air pollution.

The fire tube boiler section is updraft and cannot achieve nearly the efficiency of a downdraft heat exchanger because the exhaust gases are exiting next to the hottest water in the boiler.

How the Seton Boiler is Different

Most wood burning furnaces and wood boilers on the market today are unable to sustain a temperature of 1100º F or higher.

They are built with a firebox made of steel which is surrounded by a jacket of water, "wood stove in a water tank design". This water jacket serves two purposes: it transfers heat from the firebox to the home heating system, and it cools the steel firebox and keeps it from melting.

The problem is, by keeping the firebox cool, the water jacket also cools the fire and prevents it from burning at temperatures needed for complete combustion.

That's why these units produce irritating smoke and potentially dangerous creosote.

The Seton wood burning boiler is built in an entirely different way.

Our firebox is made of high strength ceramic refractory, cast four to six inches thick using a compression casting method, and surrounded by outer layers of insulation designed to keep the heat in.

The compression casting makes our refractory stronger than the companies that have copied our boiler design.

This has the ability to increase the strength of the firebox as it heats up. The natural draft system pulls air into the furnace which fans the flames and creates a roaring fire with sustained temperatures of 1800º to 2400º F.

Heat from the fire is captured by a water tube heat exchanger located above the firebox in the path of the escaping superheated gases.

The pressure vessel extracts the radiant heat from the flames and escaping gases by convection, and not from the combustion process. This innovative design enables the Seton Boiler wood boiler to burn cleanly and operate at a very high level of efficiency.

By the time the escaping gases leave the boiler, they have cooled to around 400º F. The 1700º F difference in temperature between the firebox and the vent represents the amount of energy captured to heat your home.

The Seton Wood Boiler burns clean and delivers very close to 86% of the wood's thermal energy to your home heating system

Resources:

| Specifications | Seton W-130-E | |

| Furnace Dimensions | 52"H x 48"D x 42"W | |

| Furnace Actual Net Output (BTU/Hr) | 130,000 BTU | |

| Weight | 2,800 lbs | |

| Approx Heating Capacity | Up to 5,000 sq. ft. | |

| Thermal Efficiency | Up to 80-87% | |

| Combustion Chamber Volume | 15 cu. ft. | |

| Diameter of Chimney Connection | 8" | |

| Distance From Sides to Combustibles | 12" | |

| Max Log Length | 28" | |

| Max Log Diameter (Door height is 16" on all boilers) | 26" | |

| Working Pressure | 30 Psi. | |

Be sure to check out our newly improved Cookstove Community website cookstoves.net; the best place online to connect with other cookstove users over stoves, self-sufficient living, alternative energy, and more! Take a look at our selection of videos, articles, and photos, and be sure to visit the forums to connect with like-minded folks from all over.

If you are planning to cook with a cookstove, you will need to understand some basic fire safety. Remember, extinguishing a grease or oil fire with water is not a good idea.

For help choosing and installing a wood boiler, see the links and posts below.