Portage & Main Ultimizer BL34-44 Boiler

The wood model does not meet 2016 NSPS EPA, and thus has been discontinued. The coal model with the shaker grate is still exempt exempt, and thus the coal model can be sold for residential use.

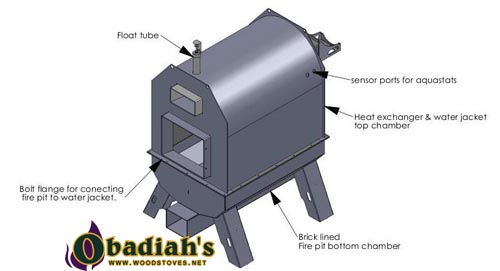

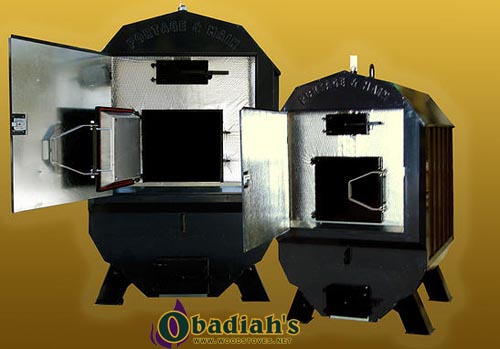

The Ultimizer BL34-44 outdoor water boiler by Portage and Main has taken their conventional boiler to new heating heights. This model is a larger version of the BL28-40, heating almost twice as much area but with the same innovative design. The increased heat is provided in this furnace by adding large amounts of refractory cement and firebrick to the fire chamber. In addition, the water furnace is also supplied with a fan for forced air combustion to regulate the burning rate.

The Ultimizer can also be fitted, if desired, with a shaker grate and agitator handle to burn coal. Either way, wood or coal, the BL34-44 boasts high efficiency and years of safe convenient heat.

- Description

- Specifications

- Photos (7)

- Pricing

- Videos (1)

- Add Review

Portage and Main’s Utimizer BL28-40 is one hot boiler. The innovative refractory cement, actually 2 ½ inches of stainless steel fiber reinforced pre-cast cement, plus four inch thick refractory firebrick provides much hotter temperatures for proper, most complete, combustion which translates to a cleaner more efficient burn.

The multi-pass heat exchanger, water cooled baffle and reverse turn heat exchanger, allow for maximum heat transfer of heat from the flue gases prior to exiting through the insulated chimney.

The hotter burn of this boiler, in addition to other design features – listed below, eliminates many corrosion problems that can be found in other boilers with lower burning temperatures increasing the life of the furnace.

Click here for Single Line PEX Pipe

Click here for Dual Line PEX Pipe

Features:

Rounded fire chamber top and 2 1/2” stainless steel fiber reinforced, precast refractory cement, line the bottom 12” of the fire chamber – all 4 sides

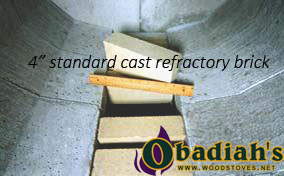

Grates are constructed of standard cast refractory brick, 4” thick providing more heat and preheated air introduction into the fire chamber – bricks can also be easily adjusted to ensure coals stay in as well as convenient ash removal

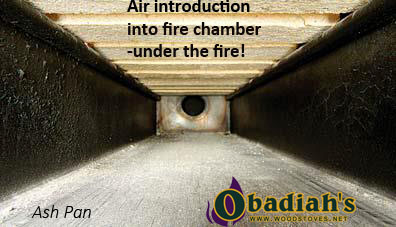

Air introduced under the fire makes a much hotter fire

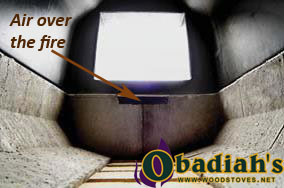

Air added above the fire is beneficial for complete combustion, as coals are developed more air is added above the fire, now in stage 2 combustion resulting in a cleaner/more efficient burn of the smoke and flue gases

Digital Johnson Controls regulate temperature, programmable within one degree

Aquastats maintain the water temperature at the desired level

High limit safety aquastat allows the furnace to be controlled, keeping the water from overheating or boiling if the Johnson Controls fail

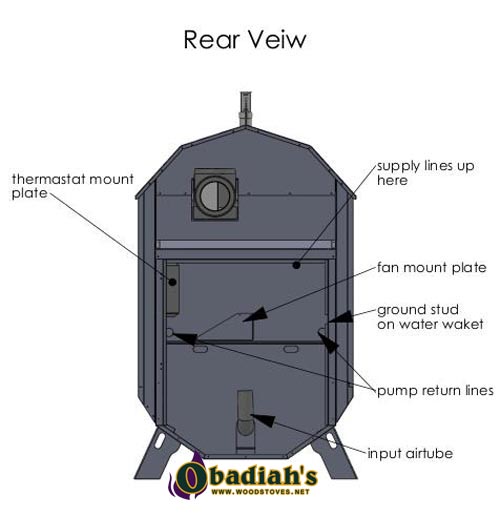

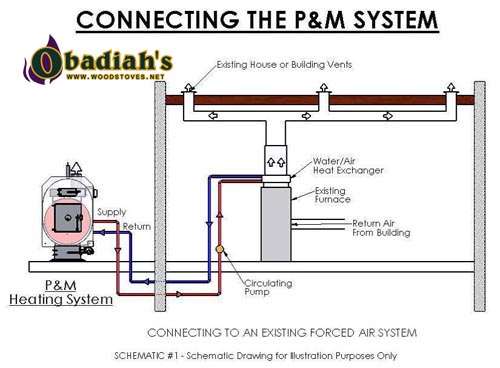

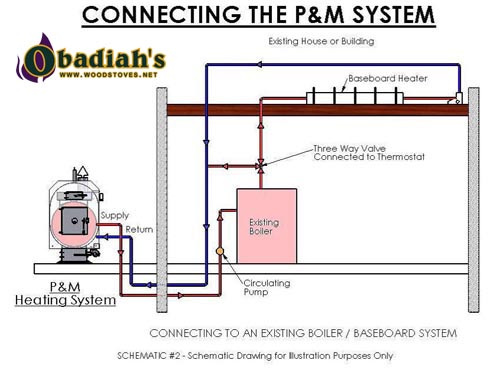

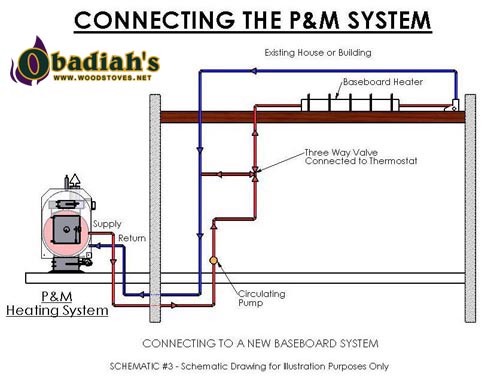

Two supply ports/two return ports located in the rear cabinet which is a easily accessible warm/dry spot for blower motor, aquastats, electrical connections, circulators, air box with built in damper as well

Convenient Float makes it easy to see the water level

Chimney connection out the back of boiler helps prevent roof leaking and stack corrosion

Interior doors are sealed top quality gaskets with built in hi-temp silicone while the outer cabinet door is insulated to prevent cooling and cooling effects on the interior doors

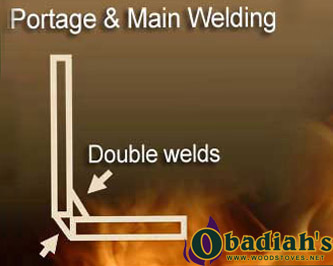

Double welded boiler style joints, welding inside and out - Exclusive to Portage and Main Water Furnaces

Fire chamber and heated exchanger are made of 1/4” W44 cold rolled mild steel

Inside water jacket made of 1/4” cold rolled steel

Outside water jacket made of 3/16” cold rolled steel

Furnaces are well insulated with R20 fiberglass which reduces condensation, resulting in less corrosion and Roxull quality insulation (2200 degree) providing no break down, cracking separation or burning of insulation

Easy ash pan removal and ashes can be quickly cleaned out without the need to put out the fire

The Ultimizer Series has legs, therefore no concrete pad is necessary for installation, also added height makes a more convenient fill level

Optional Features:

Manual coal loading is an option for the Ultimizer furnace. (This is the coal shaker grate version of the Ultimizer BL28-40.)

Resources:

| Specifications | Portage & Main Ultimizer BL 34-44 Boiler | |

| Maximum Furnace Output (BTU/hour) | 370,000 | |

| Heating Area (sq. ft.) | Up to 8,000 | |

| Size Total W x D x H | 50” x 80” x 82” | |

| Shipping Weight (lbs) | 2,800 | |

| Chimney Size | 8” | |

| Door Size W x H | 20” x 18” | |

| Fire Chamber W x H x L | 34” x 44” x 44” | |

| Surround Fire Brick Height | 14” | |

| Water Capacity (US gallons)* | 120 | |

| Horizontal Flat Tube Heat Exchanger | 6” x 11” x 8’ *** | |

| Heat Exchanger | Multi-Pass Reverse Turn | |

| Maximum Log Length | 44” | |

| Split Wood or Suggested Log Diameter | Will burn wood as large as you want to handle** | |

| Electrical Requirement | 120 Volt | |

| Power Draft Motor | Yes | |

| Limited Warranty | 20 Year | |

* Extra water volume is usually a by product of a large firebox because of inefficient design. Think of which pot boils faster— a big one or a smaller one? Consider the extra cost of treating larger volumes of water or propylene glycol if required.

** Splitting logs will facilitate faster seasoning of the wood.

*** Does not include any vertical heat exchange, ie: baffle at back of fire chamber.

*Shipping is not included.

Please call or email us today for a quote on pricing and shipping.

CLICK HERE TO VISIT OUR NEWER WEBSITE WHERE YOU CAN FIND PRICING AND MORE INFORMATION

Portage and Main Ultimizer Series