Eko 25 Line Boiler - Discontinued*

*PRODUCT DISCONTINUED - This page is for informational purposes only.

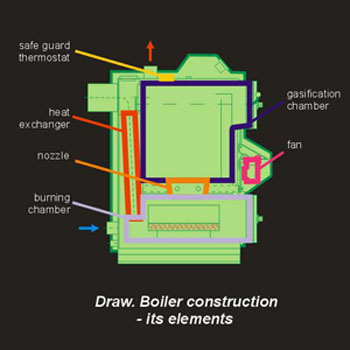

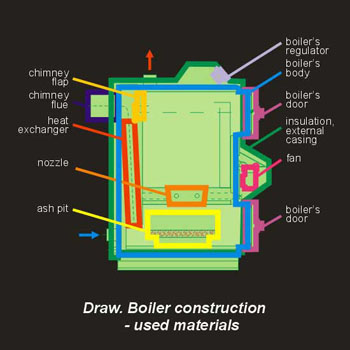

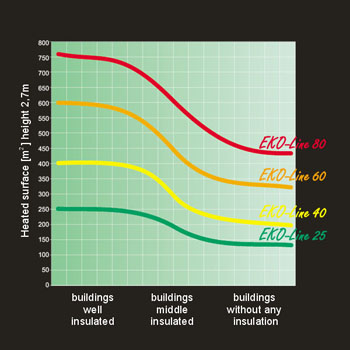

EKO Line boilers provide a convenient, safe and environmentally friendly way to heat your home and domestic hot water with wood. EKO boilers assure the independence and self-reliance that heating with wood provides. Because the Eko-Line boilers use wood gasification combustion, they give unusually high overall heating efficiency. They use substantially less wood than conventional boilers and outdoor water stoves with no visible smoke when fully operating.

- Description

- Specifications

- Photos (4)

- Pricing

- Extended Info

- Add Review

|

Resources:

| Specifications | EKO 25 | |

| Power Range | 85,000 | |

| Weight | 1280lbs | |

| Height | 51.5" | |

| Height of Heating Water Exit | 48.5" | |

| Height of Heating Water Entry | 8.3" | |

| Height of Outlet Valve | 5.1' | |

| Height of Chimney Flue | 37.4" | |

| Width Including Handle | 24.8" | |

| Width Including Casing | 23.6" | |

| Depth | 41.1" | |

| Hot Water Exit | 12.6" | |

| Diameter of Chimney Flue | 8.0" | |

| Diameter of Hot Water Exit | 2.0" | |

| Diameter of Hot Water Entry | 2.0" | |

| Kind Of Connection | Thread | |

| Drain Diameter | 0.5" | |

| H2O Capacity | 20gal | |

| Fire Box Volume | 31gal | |

| Power Consumption | 50watts | |

| Wood Moisture | 15-25% (Recommended) 10-35% (Acceptable) | |

| Max Log Diameter | 7" | |

| Max Log Length | 20" | |

| Average Flue Temp | 340°F | |

| Max Working Pressure | 25 PSI | |

| Required Chimney Draught | 15-20 Pa | |

| Volt/Frequency | 120/60Hz | |

| UL/CSA Tested and Certified | Yes | |

| Warranty | Limited 20 years | |

Be sure to check out our newly improved Cookstove Community website cookstoves.net; the best place online to connect with other cookstove users over stoves, self-sufficient living, alternative energy, and more! Take a look at our selection of videos, articles, and photos, and be sure to visit the forums to connect with like-minded folks from all over.

If you are planning to cook with a cookstove, you will need to understand some basic fire safety. Remember, extinguishing a grease or oil fire with water is not a good idea.

For help choosing and installing a wood boiler, see the links and posts below.