95% of all underground pipes leave no gaps between the feed and return PEX lines. When you consider the BTU bleed off factor you get when you bury this low R value pipe in the ground, not to mention the very low R-Values, I wonder how the contractor could sleep at night. So many BTUs are cancelled out in the pipe before they reach the place where the BTUs are needed. In a water to air heat exchanger, this can be a problem on really long runs. My advice is, if you’re going with an outdoor boiler, run two corrugated lines with two hot feeds in one pipe and two cold returns in the other. Don’t skimp here; otherwise you’ll be heating the ground next to your home and not your home or shop. Here is a good place to see what has happened to others. http://www.hearth.com/talk/threads/insulated-underground-pex.48808/

In some cases when you are heating several separate buildings, moving heat between them underground, is necessary. If you must bury your feed and return in the ground, do it right the first time, since digging it back up again is very expensive. So let’s take a look at what kind of underground PEX pipe is available. Consider this; even if you live in Georgia, the soil temps in the winter are within about 20-30 degrees of Montana temps below our frost line. The key is how deep you bury your pipes. In northern climates most folks dig below the frost line for their area. Where I live that is 7’. At 7’ depth the ground pretty much stays in the 50 degree range. See my point? The water lines that feed our outdoor water hydrants are buried that deep so they don’t freeze.

When you look closely at underground PEX pipe you’ll find lots of variations. In my opinion, you want the highest R value possible for as long as possible. The ground is a cold damp place and most insulation will become waterlogged and lose their R-values. In most high efficiency wood boiler installs we are looking for as many BTUs per pound of wood as possible. To do this requires that most of the BTUs stay inside the PEX until they arrive where they are most needed. Therefore we use two separate lines, one for the feed, and one for the return. I run them separately instead of all inside one pipe, because it is very hard to insulate the cold return from the hot feed inside one pipe. Of course most outdoor wood boilers are so inefficient, line loss does not matter either.

You can save a lot of chopping and wood handling by reducing the amount of BTU loss in your installation. Here are some pictures of various underground PEX systems and what to watch out for. The type of pipe shown has very low R-Value and will lose lots of BTUs. Notice the air space and no insulation between the Feed and Return. This is very bad.

You can save a lot of chopping and wood handling by reducing the amount of BTU loss in your installation. Here are some pictures of various underground PEX systems and what to watch out for. The type of pipe shown has very low R-Value and will lose lots of BTUs. Notice the air space and no insulation between the Feed and Return. This is very bad.

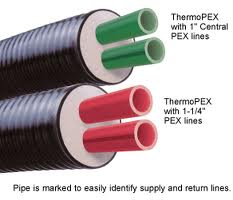

Next if you look at this pipe it has more wraps and is better insulated, but still has just one wrap of insulation between the Hot Feed and Cold Return. Still not good as they work to cancel each other out in the end. Your hot feed temps will be much lower as they have been cooled by the cooler return line temps. Bury your Feed and Return lines separately using underground pipe like ThermoPEX shown on the right.

Next if you look at this pipe it has more wraps and is better insulated, but still has just one wrap of insulation between the Hot Feed and Cold Return. Still not good as they work to cancel each other out in the end. Your hot feed temps will be much lower as they have been cooled by the cooler return line temps. Bury your Feed and Return lines separately using underground pipe like ThermoPEX shown on the right.I have also done the same thing above ground on short runs that we can enclose with both rigid and spray polyuerathane 2 part expansive foam. This foam can absorb water and it will loose its R value if it gets damp. So it is very important to protect all foam from moisture. It is easiest to keep moisture out above ground. Below ground is always going to be damp and eventually your R Values will drop over time. A simple roof to shed water above the pipe when it is installed above ground works well.

Posted on Saturday, January 5, 2013

.jpg)

.jpg)