GARN WHS-Junior (1000) Wood Boiler Heating System - Not Available for sale

This product is no longer being sold by Obadiah's.

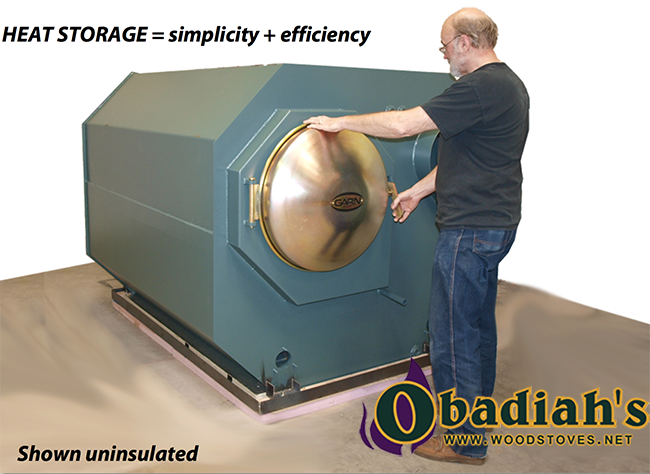

This unit will be tested for EPA NSPS in March 2016. The GARN® WHS-1000 Junior is a simple, efficient, and durable wood residential heating unit. The GARN® system is a state-of-the-art wood fired hydronic heating system with 30 years of tested technology and experience. GARN® wood burning boilers use a large hydronic thermal storage tank to store the heat from a fast, clean, and efficient wood burning gasification process. GARN® wood heating systems can burn cord wood, slab wood, pallets and other scrap wood, dense wood briquettes, and air-dried corn on the cob. GARN® hydronic heaters produce virtually no smoke because of its patented, two-stage wood gasification technology. A GARN® is not an outside wood furnace, outside wood boiler or an outside wood stove. However, it can be installed outside in a shed. The GARN® is installed indoors and provides hot water for heating your home, shop, business, or district heating system. All of our models combine high-efficiency wood combustion and hydronic thermal storage to produce the most efficient and simple wood heating units on the market.

- Description

- Specifications

- Photos (4)

- Pricing

- Extended Info

- Videos (10)

- Add Review

Features

- Integrated Combustion

- Non-Pressurized Thermal Storage

- Double Weld Construction

- Secondary Combustion (Gasification) Chamber

- 5 Pass Heat Exchanger

- Large Insulated Loading Door

- Double Lock Safety Handle

- Hot Water Return (HWR) Dispersion Tube

- Manway Access

- Induced Draft Fan

- Air Cooled Door

- Combustion Air Supplied from Outside

- 30 Years of Proven Technology

Benefits of a GARN® Boiler

- Safe and Certified to be Installed Indoors

- No Overnight Loading or Fire Required

- Long Life, Low Maintenance Construction

- Reduced Wood Use

- Low Emissions

- Easy to Load Fuel Chamber

- Cool to the Touch Loading Door

- No Smoke in Your Face when Reloading Fuel

- Easy Maintenance

- Simple Part Replacement

- Anodes with Water Treatment Minimize Corrosion

- Demonstrated Longevity

- Available Electric Backup

- Only rear vent wood boiler on the market!

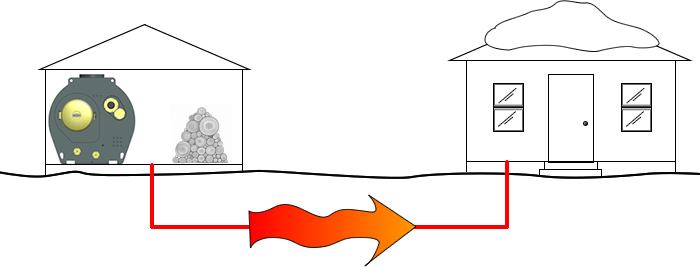

Listed below is a overview of the various parts of the GARN® WHS and their purpose. Its best to think of the GARN® WHS as a big tank of water that you heat by burning wood. The fire is not modulated, the entire wood load is burned quickly while the heat is dumped into the large water tank. This results in a very clean, highly efficient burn. The outcome is less wood, less work, and less smoke, for the consumer. When a thermostat calls for heat, a pump turns on drawing the hot water out of the tank and into your heated space for distribution.

BURNING AND HEAT STORAGE:

1. Fresh air is ducted from the outside and enters the unit through an inlet in the back.

2. The fresh air travels through a tube immersed in the water and into the air collar.

3. The fresh air is circulated around the air collar before entering the combustion chamber. This keeps the collar relatively cool. The air collar distributes the air into the combustion chamber.

4. In the combustion chamber the wood burns in its first stage.

5. The smoke and exhaust from the fire enters the insulated reaction chamber. Additional fresh air is provided by the air collar. A high temperature secondary combustion occurs. The process is called direct gasification. Direct gasification burns the smoke and creates additional heat.

6. After exiting the reaction chamber the clean exhaust travels through 30 ft of tubing. Heat transfers from the very hot gases to the water in the tank.

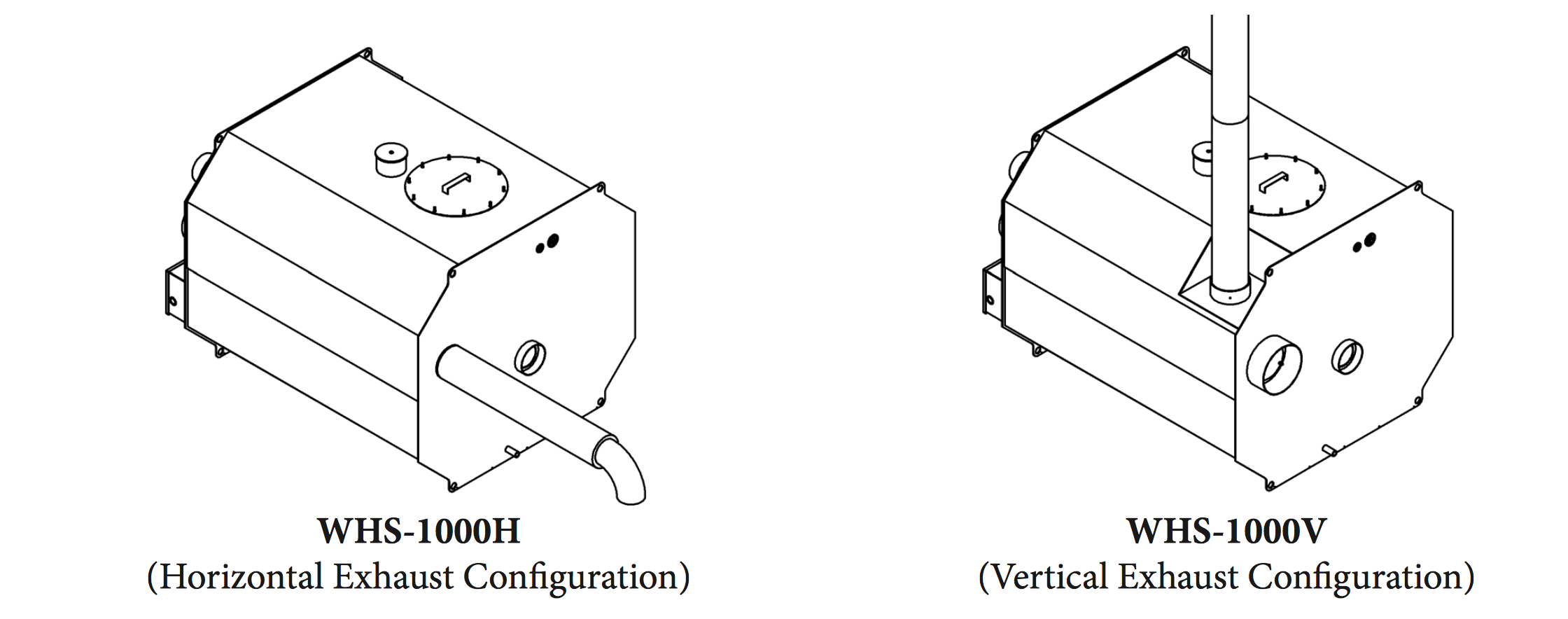

7. The exhaust exits the GARN® WHS vertically or horizontally through a 6” insulated flue.

8. A digital controller automatically stops the induced draft blower when combustion is complete. The water is now hot and ready to be used for heat in a building.

OVERVIEW AND OPERATION:

- A GARN® WHS needs to be installed indoors. A designated area in a building, a separate building, or an attachment to an existing building is required.

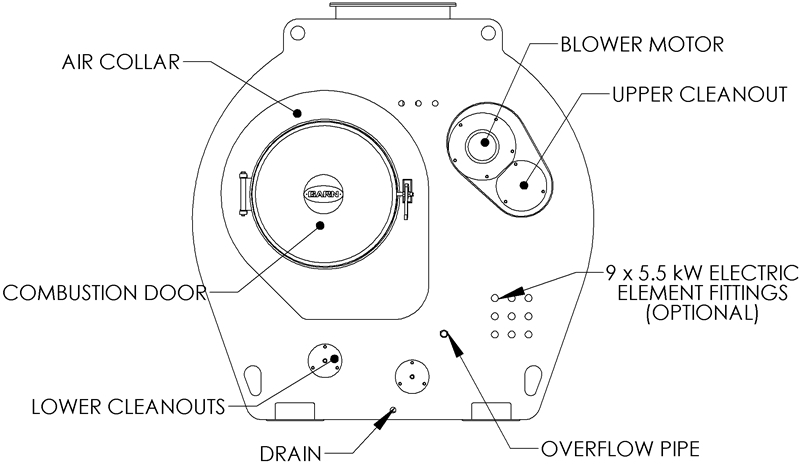

- This is the front of the GARN® WHS unit. The front is where you load wood, mount the blower, access the digital controller, drain the unit (when needed), and access the cleanout ports for periodic pipe cleaning. An overflow pipe is also provided so the first time you heat your unit the water that expands to the top of the tank comes out here. The GARN® WHS provides optional off-peak electric elements fittings up to 49.5 kW.

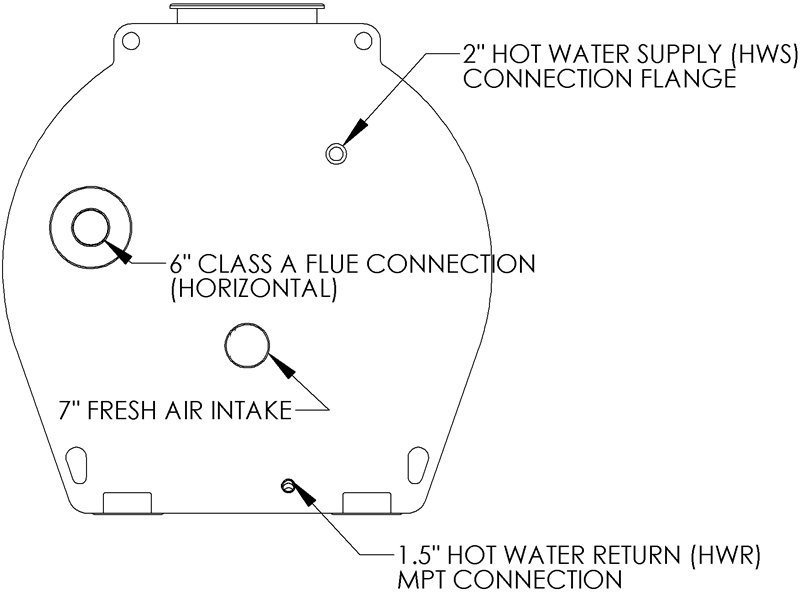

- This is the back of the GARN® WHS. The back is where you connect to the 2” hot water supply (3” on the WHS 3200) and 1.5” hot water return (2.5” on the WHS 3200), duct the fresh air intake, and vent with the horizontal exhaust (if applicable).

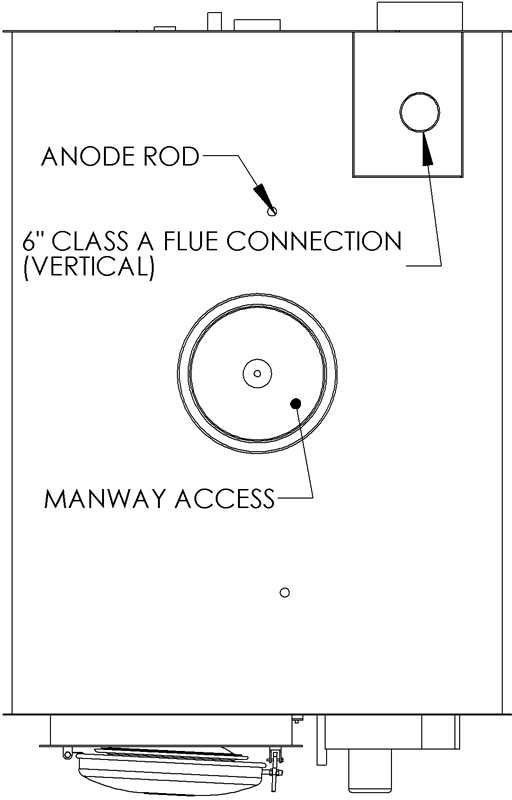

- This is the top of the GARN® WHS. The top is where you access the full-size manway (for water inspection and water chemical addition), anode rods (for corrosion protection), fill the tank with water, and vent with the vertical exhaust (if applicable).

- Start a fire by loading the combustion chamber and adding some newspaper and small kindling. A simple match does the trick. The fire will heat up the tank of water.

- Reloading after a fire is easy, just open the combustion door. The induced draft blower ensure little to no smoke backdrafts into your space. You can then pile on more wood to get the water up to your desired temperature.

- When your building calls for heat, a pump in your system turns on and draws the hot water from the tank and distributes it for heat. A fire need not be maintained constantly. That’s the idea behind storing the heat.

- The GARN® WHS is not pressurized and so cannot be directly connected to a pressurized system. The GARN® WHS can interface with a pressurized system by simply installing a heat exchanger.

- When the GARN® WHS unit drops below the operating temperature of your system, start a fire and heat the water again.

Resources:

| Model Specifications | GARN® WHS-1000 (Junior) | |

| Maximum Heat Output † | 180,000 btuh | |

| BTU’s of storage (120 F to 195 F) | 630,000 btus | |

| Tested Efficiency (LHV) | 80.0% * | |

| Particulate Emissions output – PM2.5 | 0.190 lbms/mmbtu | |

| Particulate Emissions rate – PM2.5 | 2.31 gr/hr | |

| Nominal gallons of storage | 980 gallons | |

| Weight – Empty | 2,200 lbs. | |

| Weight – Filled | 10,370 lbs. | |

| Recommended wood length | 16″ to 24″ | |

| Recommended wood diameter | 3″ to 10″ | |

| Combustion chamber length | 36″ | |

| Combustion chamber diameter | 23″ | |

| Combustion chamber volume | 110 gallons | |

| NPT supply flange | 1-1/2″ (18 gpm MAX) | |

| MPT return pipe | 1″ | |

| Draft inducer motor | 1/2 HP | |

| Electrical requirements | 115 VAC 15 amp | |

| Flue diam. (2100°F Class A) | 6″ | |

| Air intake diam. (single wall) – Includes screened intake hood | 7″ | |

†Maximum heat output is based on reloading once every 3 hours with 24 inch long split white oak, with 20% moisture content. Output rate is fuel dependent and will vary with wood type, moisture content, size and reloading frequency. GARN® WHS units are certified safe to burn cord or slab wood, densified wood briquettes and air dried corn on the cob.

*Tested to ASTM-E2618

Be sure to check out our newly improved Cookstove Community website cookstoves.net; the best place online to connect with other cookstove users over stoves, self-sufficient living, alternative energy, and more! Take a look at our selection of videos, articles, and photos, and be sure to visit the forums to connect with like-minded folks from all over.

If you are planning to cook with a cookstove, you will need to understand some basic fire safety. Remember, extinguishing a grease or oil fire with water is not a good idea.

For help choosing and installing a wood boiler, see the links and posts below.

Garn WHS Wood Boiler Unit Overview

Garn WHS Wood Boiler Unit Overview Rear

Garn WHS-1000 Junior Wood Boiler Product Video

Gary Wood Boilers - Starting a Fire

Garn Maintenance: Blower Wheel Removal

Garn Maintenance: Replacing Blower Wheel

Garn Maintenance: Door Gasket Replacement

Garn Maintenance: Heat Exchanger Cleaning

garn Maintenance: Replacing Manway Gasket

Garn Maintenance: Removing Ash